Trampoline parks have become one of the most popular recreational spaces in recent years. Families, schools, and businesses invest in these parks to create safe and fun environments. But many people wonder: how does the trampoline park manufacture process actually work? Understanding the steps, materials, and safety measures is crucial for anyone interested in opening or visiting such a facility.

What Is Trampoline Park Manufacture? (Quick Answer)

Trampoline park manufacture is the process of designing, producing, and installing trampoline-based entertainment areas. It includes everything from planning the layout and choosing durable materials to ensuring international safety standards. In short, it is a combination of engineering, creativity, and safety expertise that transforms an empty space into a fully functioning trampoline park.

Step by Step: How Trampoline Parks Are Manufactured

To better understand the process, here is a simplified guide showing how a professional trampoline park manufacture project is typically completed:

1. Planning and Design

- Investors and manufacturers begin with a needs analysis.

- The layout is created based on available space, target audience, and chosen activities.

- Safety zones, walkways, and emergency exits are added to the plan.

2. Material Selection

- Strong galvanised steel is used for frames to ensure durability.

- Jumping mats are made of UV-resistant and fire-retardant fabrics.

- Protective padding and foam are chosen for safety and comfort.

3. Safety Compliance

- Every trampoline park must follow international regulations such as ASTM or EN standards.

- Tests are conducted on springs, welds, and padding thickness.

- Manufacturers provide documentation proving compliance.

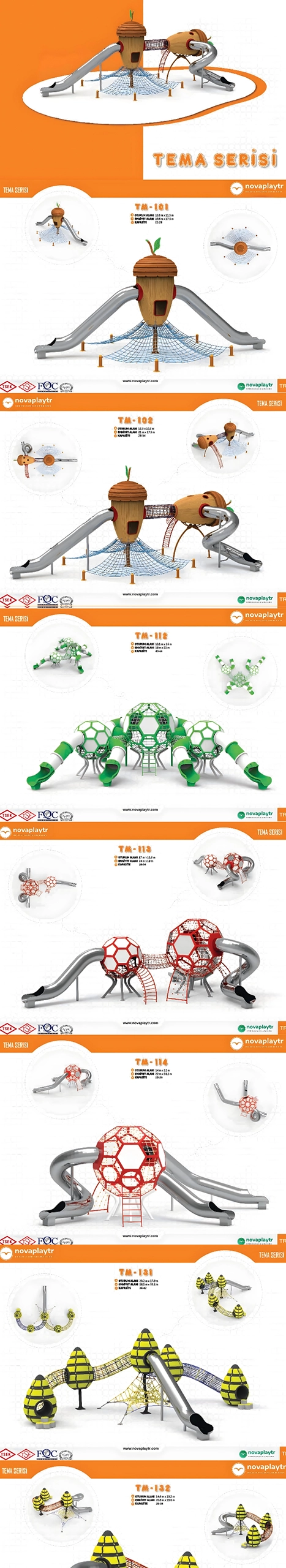

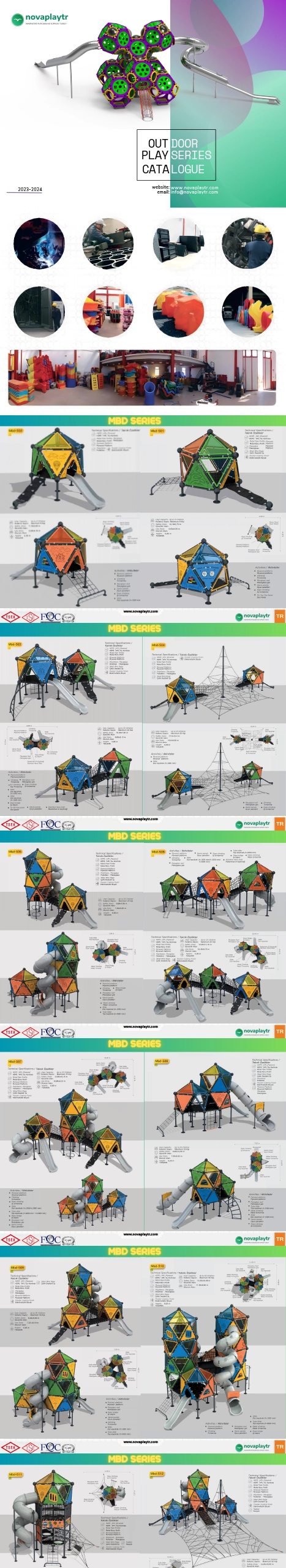

4. Production and Customisation

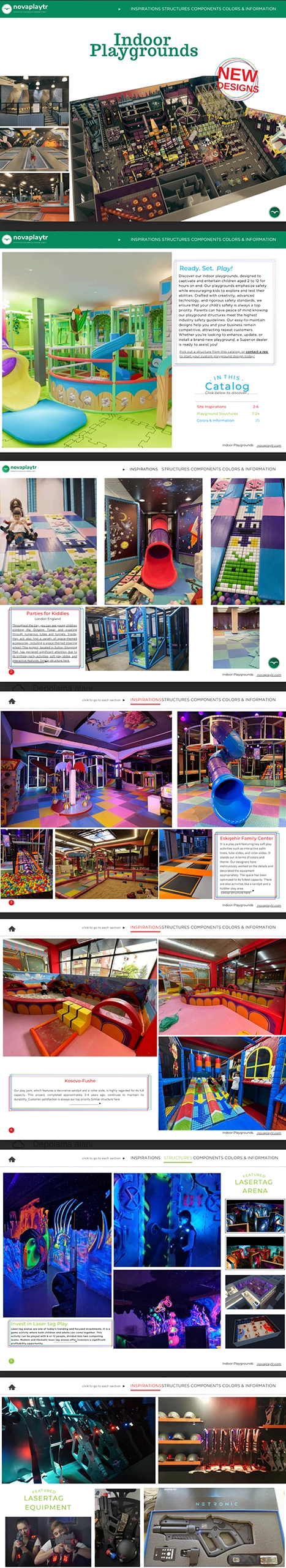

- Trampolines, climbing walls, foam pits, and other attractions are produced in specialised facilities.

- Colours, branding, and themes can be customised according to investor preferences.

- For example, a park for younger children may use soft play areas, while an adventure-focused park may feature ninja courses.

5. Installation on Site

- Professional teams assemble the steel structures, mats, and protective elements.

- The layout is double-checked to ensure accuracy and safety.

- Staff members may also be trained in maintenance and safety protocols.

6. Final Inspection and Opening

- A full safety inspection is conducted before opening.

- Only after approval can the park welcome visitors.

- Regular maintenance is scheduled to extend the lifespan of equipment.

Frequently Asked Questions (FAQ)

How long does it take to build a trampoline park?

The timeline depends on size and complexity. On average, trampoline park manufacture can take between 2 to 6 months, from design approval to final installation.

What safety measures are included in manufacturing?

Manufacturers use padded edges, fire-resistant fabrics, strong springs, and secure frames. Compliance with international standards ensures reduced risks for users.

Can trampoline parks be customised?

Yes. Investors can choose colours, branding, and activity types. A park for families may look different from one focused on extreme sports or fitness training.

How much does it cost to set up a trampoline park?

Costs vary widely depending on size, features, and location. A small park may require a modest budget, while a large-scale facility with digital integrations can be a significant investment.

Do manufacturers provide after-sales support?

Reputable manufacturers usually offer warranties, spare parts, maintenance services, and training for staff. This ensures long-term safety and customer satisfaction.

Conclusion

The process of trampoline park manufacture involves much more than simply building trampolines. It requires careful planning, high-quality materials, strict safety compliance, and professional installation. Investors who partner with experienced manufacturers can create spaces that are both profitable and trusted by families.

Trampoline parks are more than just entertainment—they are environments where safety, design, and fun meet. Whether you are planning to open your own park or simply curious about the process, knowing how these parks are manufactured helps you appreciate the work behind every jump.